STEMGEL™ Underground Stemming Solutions

Unlock the Benefits of STEMGEL™

--

Reduce Risk, Enhance Safety, and Achieve Better Blasting Results

Unlock the Benefits of STEMGEL™ -- Reduce Risk, Enhance Safety, and Achieve Better Blasting Results

Get a Quote Now

Request a Trial of STEMGEL™

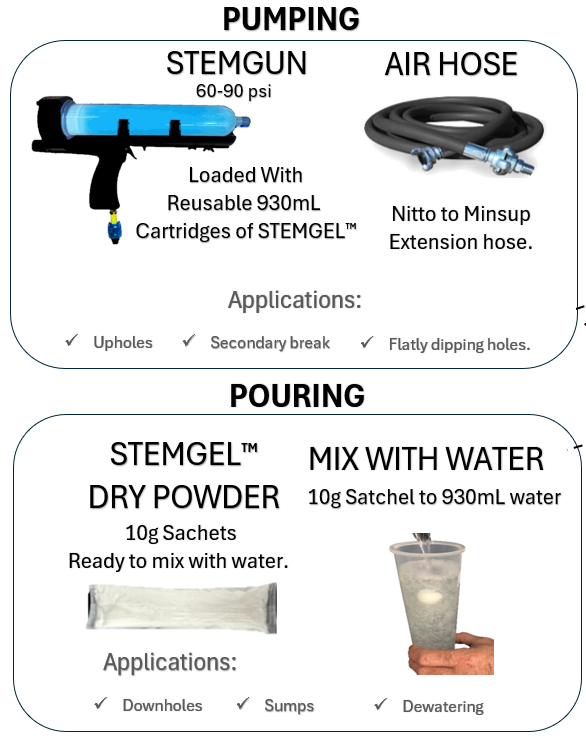

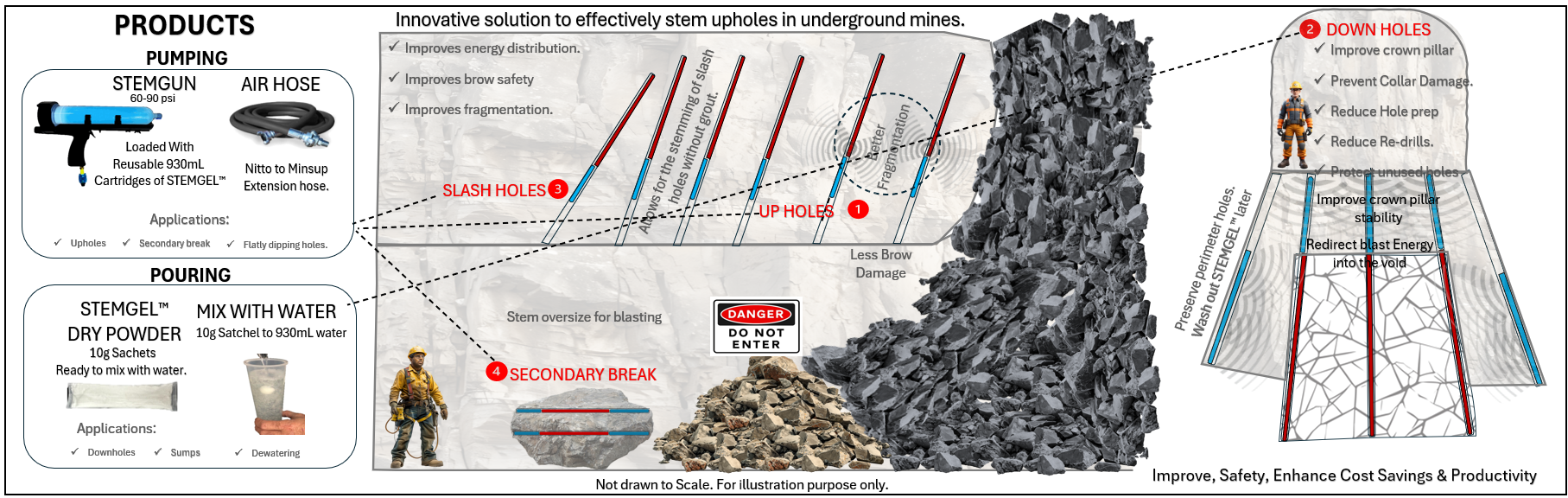

How is STEMGEL™ applied underground?

STEMGEL™ is easily prepared on site by mixing a 10g satchel of dried STEMGEL™ Powder with 930mL of Water. Once mixed, it can be pumped or poured.

Pumping

Suitable for upholes, secondary break and flatly dipping holes.

STEMGUN requires the STEMGEL™ to be mixed and placed in the reusable 930mL and 60-90 psi of air pressure and an air hose.

Pouring

Suitable for down holes, sumps and dewatering applications

STEMGEL™ can be mixed with water and poured or the powder can be added to a wet hole or sumps or drains as a super absorbent and coagulating substance.

Why should STEMGEL™ be used Underground?

Aggregates vs STEMGEL™

Hole Blockages

Aggregates can cause blockages in blast holes leading to costly hole prep and re-drilling.

Uphole stemming

While aggregates are suitable for downholes, they can’t be used in upholes.

Flat Dipping and Slash Holes

Aggregate stemming is not easy to get into flatly dipping holes.

Blast Hole Collar Damage

Aggregates confine blast gasses however they do not fully prevent blast wave energy reaching the collars of the holes.

Stemming Removal

Once in place, it is very difficult to remove the aggregates without a special suck truck.

Production & Secondary Break

STEMGEL™ offers tangible benefits when utilized in the following applications underground

Stemming of Upholes

Stemming of Downholes

Stemming in Slash Holes

Charge Decking to separate charge columns

Secondary break and oversize blasting

Water absorption in blast holes

Stemming of subvertical or flatly dipping holes

Low void ratio blasting applications

Dust Suppression, dewatering and absorbing of water in sumps and drains

Stemming through adverse geological features

Properties of STEMGEL™ that make it ideal for stemming underground:

Reflects Blast Energy

It’s near zero Shear Modulus enables it to act as an energy break, reflecting blast S-waves

Versatility

Pumpable hydrogel stemming agent suitable for holes of various diameters and angles (dip).

Where is STEMGEL™ best utilized Underground?

Super absorbent

STEMGEL™ can absorb 400-600 times its weight in water.

Easy to Transport and Apply

STEMGEL™ powder can be carried by hand.

It can be mixed with water for pumping or pouring, or applied directly as a powder to absorb water in the hole

What are the benefits of using STEMGEL™ Underground?

Safety & Risk Reduction

Improved brow stability at uphole open stopes

Reduced risk of workers exposed to unsafe ground conditions

Reduced risk from removal of stemming from blast holes

Eliminates the risks associated with grouting of holes

Effectively stems blastholes for secondary break and oversized rocks

Easy to Transport and apply with minimal manual handling

Productivity & Cost Saving

Improved brow stability blast hole collars and blast outcomes

Improved fragmentation and reduced post blast rehab and prep

Improved blast performance and potential reduction in powder factor

Cost saving by eliminating the use of grout, aggregate and stem plugs

Cost saving on drilling, crushing, aggregate and dust suppression

Cost savings for dewatering of drill holes, sump and drain maintenance.

How has STEMGEL™ performed elsewhere?

STEMGEL™ has been successfully trialled in Western Australia in 2023, delivering tangible benefits in safety, risk reduction, productivity and cost savings in both uphole longhole trials and in a development blasting trial.

The GELDrive is a delivery system for the STEMGEL that can be mounted onto an Integrated tool carrier work basket for delivery of the STEMGEL into Upholes.

STEMGEL™ can be applied to l development holes to increase face advance by stemming the blast maximizing energy usage and fragmentation.